Background

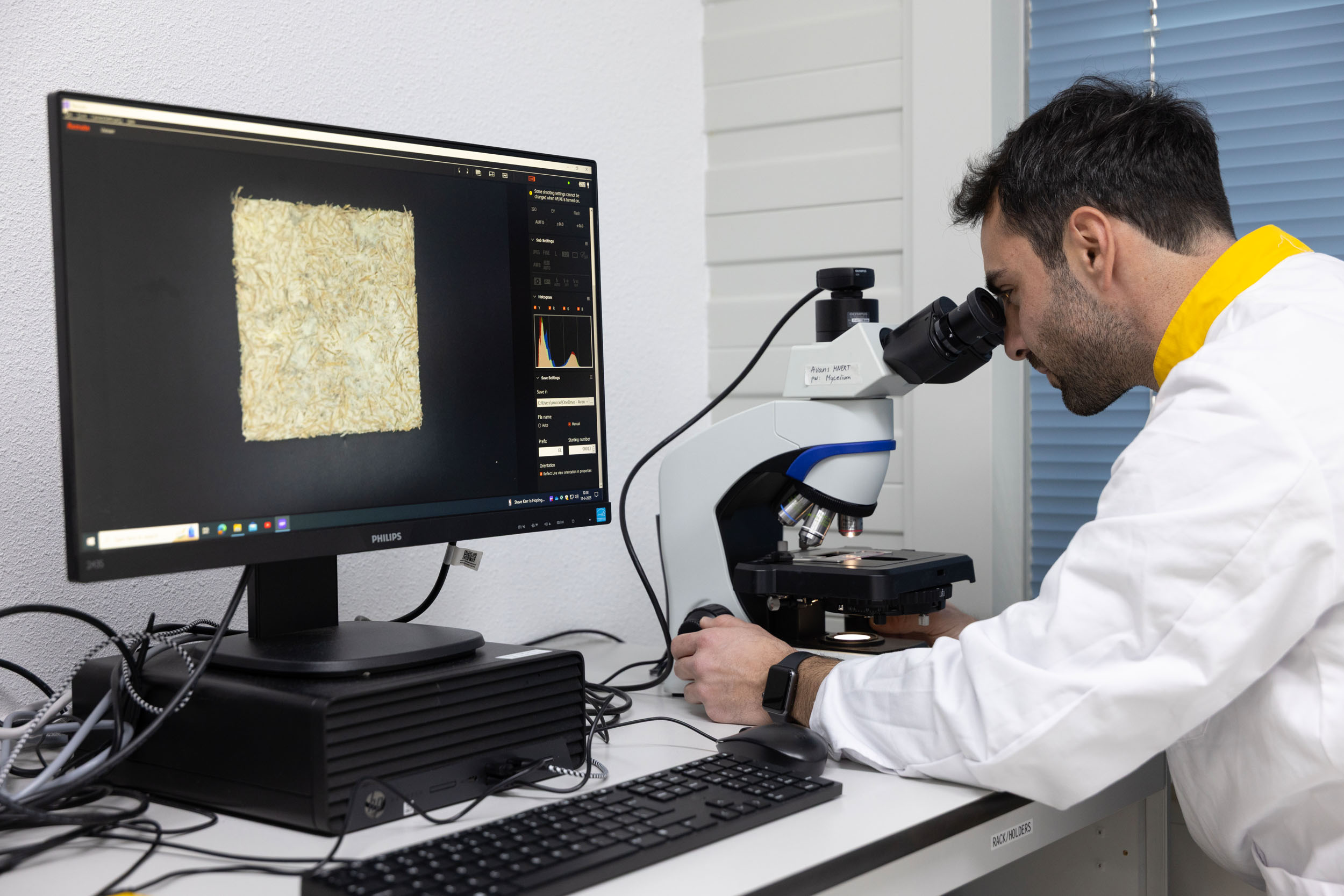

As sustainable building methods gain momentum, bio-based materials are increasingly explored as alternatives to conventional construction and insulation products. Mycelium bio-composites (MBCs) are a promising class of materials, offering a renewable, low-impact substitute for products such as MDF, EPS, and PIR insulation. In these composites, fungal mycelium grows through agricultural residual substrates (e.g. straw, hemp shives, grass, or pepper stems) and acts as a natural binder.

While mycelium bio-composites are approaching market readiness, consistent quality control remains a major challenge. Proper colonization is critical for mechanical performance and durability, yet current assessment methods are largely manual, time-consuming, and difficult to scale. To support industrial adoption, MNEXT is developing AI-based monitoring systems that can automatically assess mycelium growth and material readiness.

Assignment Description

As an intern at MNEXT, you will have the opportunity to participate in the project ‘FungAI’ which focuses on automating the assessment of mycelium bio-composites growth using artificial intelligence. Your primary role will be on the AI and data side. You will contribute to the design, training, and validation of AI models that can distinguish between properly colonized mycelium bio-composites and samples that require further growth or intervention. The resulting system will support scalable, reliable quality control for applications in packaging, construction, and fashion.

Your tasks will include:

- Develop and fine-tune AI models for assessing mycelium growth quality based on image and sensor data.

- Validate and improve model accuracy, robustness, and generalization across different substrates and growth conditions.

- Optimization and Brainstorming: Collaborate with the team to identify potential improvements to the monitoring system and outline next steps for further research.

We are looking for a student with:

- A background in Artificial Intelligence, Data Science, Computer Science, or a related field.

- Experience with machine learning and computer vision (e.g. PyTorch, TensorFlow,).

- Interest in applied AI within sustainability, bio-materials, or industrial processes.

- Ability to work independently while collaborating in a multidisciplinary research team.

Working language: we have a multidisciplinary and international team. Therefore, the language is English. Some of the researchers also speak Dutch.

Starting Date & Compensation

February 2025. The length of the internship assignment is approximately 20 weeks. The student will get an internship compensation of €350, – per month.

Contacts

- Sára Finta (sk.finta@avans.nl )

- Tim Verschuren (t.verschuren3@avans.nl )