Background information

High-temperature co-electrolysis using SOECs is a promising technology for the conversion of CO₂ and steam into syngas (a mixture of CO and H₂). Syngas can serve as a building block for synthetic fuels and chemicals, enabling the production of renewable fuels from captured CO₂ and green electricity.

SOECs operate at elevated temperatures and can achieve high electrical efficiency by utilising both heat and electricity. However, their performance, durability, and operating window depend strongly on parameters such as temperature, gas composition, current density and cell design. Understanding these parameters experimentally is essential to move from concept to reliable, scalable technology.

This internship focuses on the experimental validation of SOEC-based co-electrolysis, contributing to the broader field of CO₂ utilisation and green fuel production.

Assignment Description

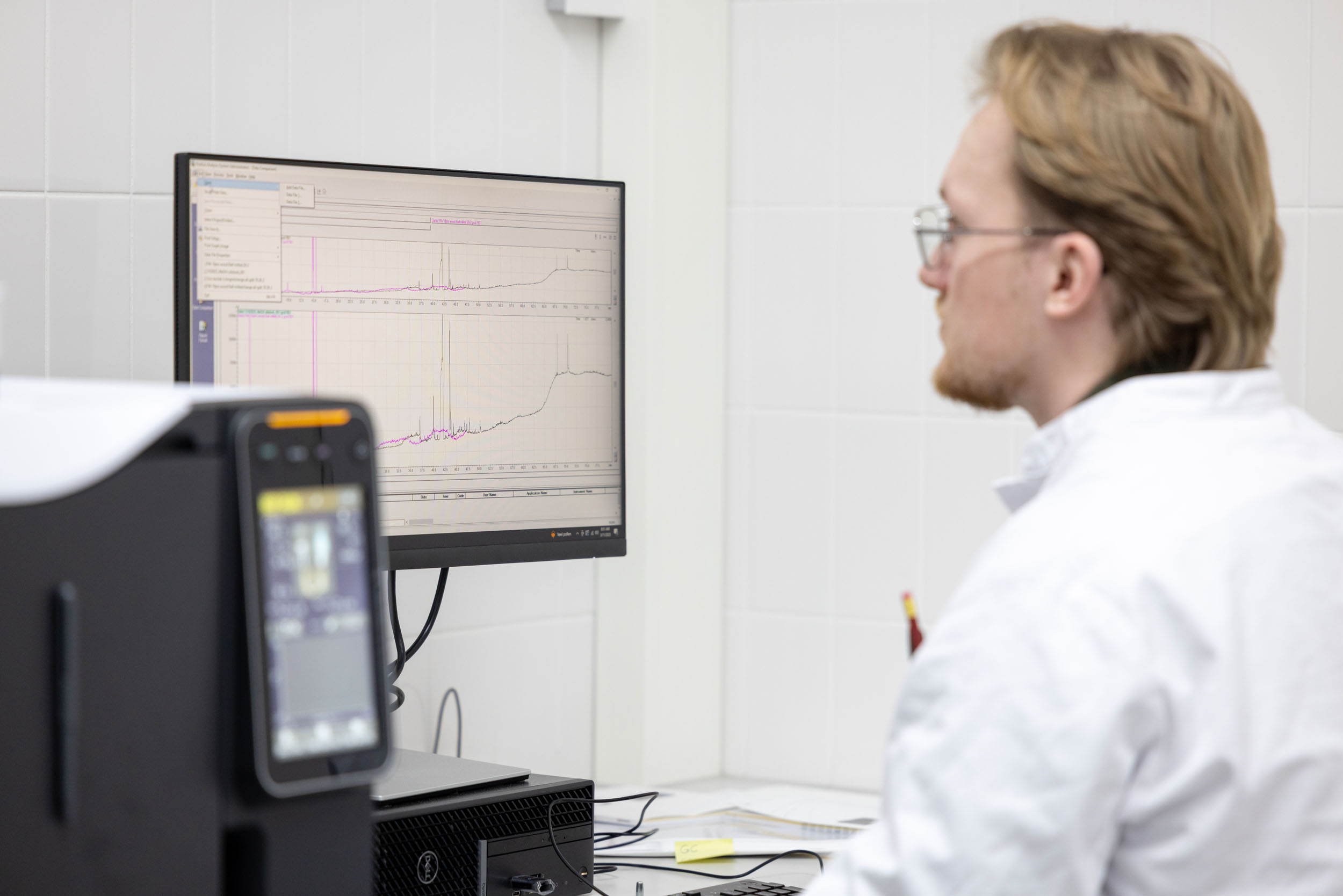

You will work with an experimental SOEC setup to study co-electrolysis of CO₂ and steam to syngas and evaluate the performance of the system under different operating conditions.

Your tasks may include:

-

Operating a Solid Oxide Electrolysis Cell (SOEC) test setup for co-electrolysis

-

Preparing and adjusting gas mixtures (CO₂, H₂O/steam, sweep gases)

-

Systematically varying temperature, current density and gas composition

-

Measuring and analysing cell voltage, current, gas composition and efficiency

-

Using instrumentation such as gas analysers and electrochemical impedance spectroscopy (EIS)

-

Comparing experimental results with theoretical expectations and literature data

-

Identifying factors that influence conversion efficiency, cell performance and stability

Research questions

-

How efficiently can SOEC technology convert CO₂ and steam into syngas through high-temperature co-electrolysis?

-

What are the key parameters influencing conversion efficiency, cell performance, and long-term stability?

Desired Skills

We are looking for a student with:

-

Background in chemical engineering, mechanical engineering, or materials science

-

Knowledge of electrochemistry, thermodynamics, and reaction kinetics

-

Practical laboratory skills and strong safety awareness

-

Experience with or interest in data analysis and instrumentation (e.g. gas analysers, EIS)

-

Interest in renewable energy, CO₂ utilisation, hydrogen technologies, sustainable energy, carbon capture and green process design

Supervision

The internship will be supervised by Dr. Agha Zeeshan Ali. Regular meetings will be held to review progress, discuss experimental results and provide feedback on methodology, analysis and reporting.

Practical Details

Start / End Date

February 2026 – June 2026

Compensation

Internship fee of €350 per month

Working language

English/Dutch