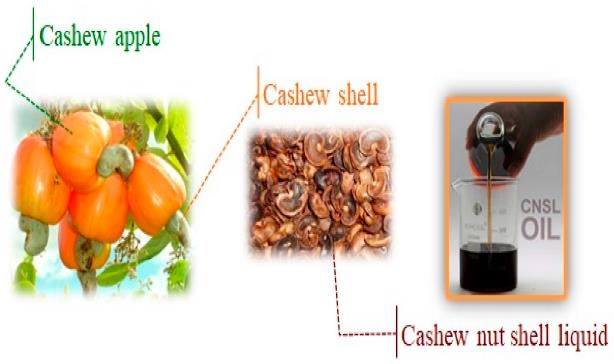

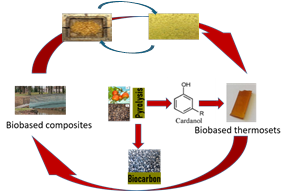

In her presentation Totally Nuts: Bio-based Epoxy Innovations with Cashew Residue, Rima explained how by-products from the cashew industry are being transformed into sustainable, recyclable epoxy resins and composites. The project focuses on a two-step pyrolysis process applied to cashew nutshells, producing two valuable outputs: cardanol (an oily substance from cashew nut shell liquid) and biochar.

Innovation in Thermosets

The extracted cardanol is chemically modified to create high-quality, biobased thermosetting resins. Meanwhile, the biochar is being explored as a reinforcing additive to improve the mechanical and thermal properties of the composites. The result is a biobased alternative to conventional epoxies, with the added benefit of recyclability, something rarely possible with traditional thermoset plastics.

Applications and Impact

The developed materials are suitable for use in coatings, adhesives, and lightweight composites for sectors such as construction, automotive, and electronics. Initial lab-scale results are promising, and small-scale upscaling trials are underway. Environmental and economic feasibility assessments are also being conducted to support future market adoption.

Broader Program

Rima Mahmoud’s presentation was part of a broader webinar lineup, which also featured contributions from researchers at Ghent University and CellMat Technologies. The event was part of the Bioresource Recovery series, aimed at building a circular materials chain through collaboration between academia and industry.