Corsair Europe

Corsair Europe is the European subsidiary of Corsair Group International and specializes in converting hard-to-recycle plastic streams into pyrolysis oil suitable for industrial reuse. Corsair operates pyrolysis plants in Thailand and Finland and is developing new plants in countries including France, Spain, Croatia, South America, and Canada. In Bergen op Zoom, Corsair operates a pyrolysis reactor dedicated to R&D purposes, capable of processing 1 ton of plastic per cycle.

Pyrolysis Process

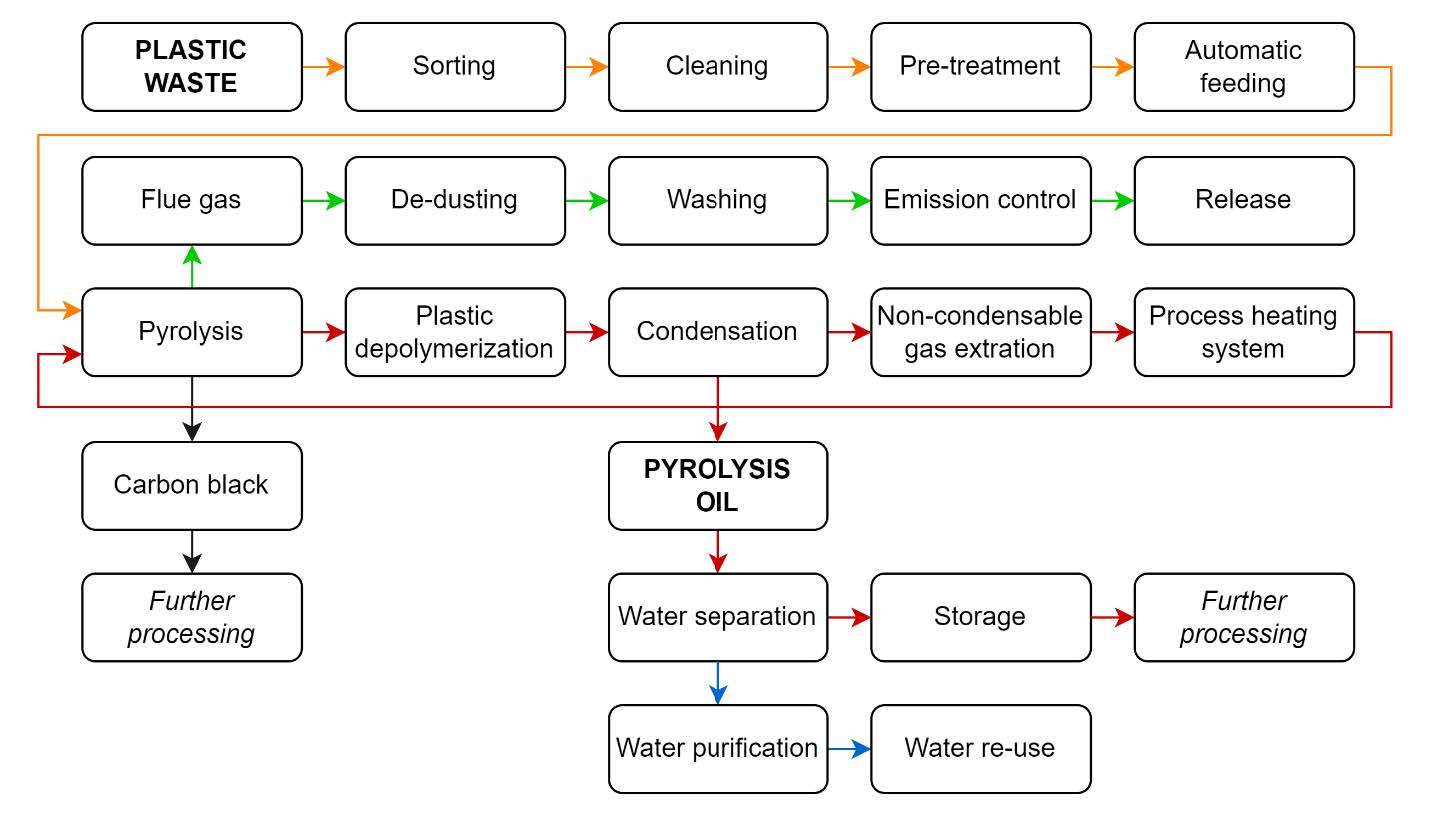

The operational process begins by loading the pyrolysis reactor with plastic feedstock. This feedstock typically comes in the form of bales, granules, agglomerates, or pellets. The process generally follows the scheme outlined below.

Once converted, the resulting pyrolysis oil is temporarily stored in dedicated tanks, analyzed, and then transported to its next destination.

Research Objectives

The main goal of this research is to study the process parameters and product properties involved in the pyrolysis of polyethylene and polypropylene for producing pyrolysis oil. Specifically, the research aims to:

-

Test and evaluate the performance of the pyrolysis equipment, including reactor stability, energy efficiency, scalability, and operational consistency under varying process conditions.

-

Optimize key pyrolysis process parameters, such as temperature, heating rate, residence time, and the use of catalysts, to maximize oil yield and improve product quality.

-

Characterize the chemical and physical properties of the produced pyrolysis oil, including parameters such as viscosity, density, calorific value, and hydrocarbon composition.

-

Assess the potential industrial applications of the pyrolysis oil, particularly its suitability as a raw material for fuel production or as feedstock in petrochemical processes.

Start Date & Compensation

September 2025

Internship compensation of €350 per month.

Desired Skills/Qualifications of the Student

The student should be capable of conducting independent laboratory and industrial research. Preferred backgrounds include chemical engineering, chemistry, electrical engineering, mechanical engineering, or mechatronics.

Contact

Contact person at Corsair: Onno Ruiter

Phone: +31 6 41462299

Email: onno@corsairnow.com; q.zhou1@avans.nl

Visiting address: Auvergnedijk 2, 4612 PZ Bergen op Zoom