From waste streams to bioplastics

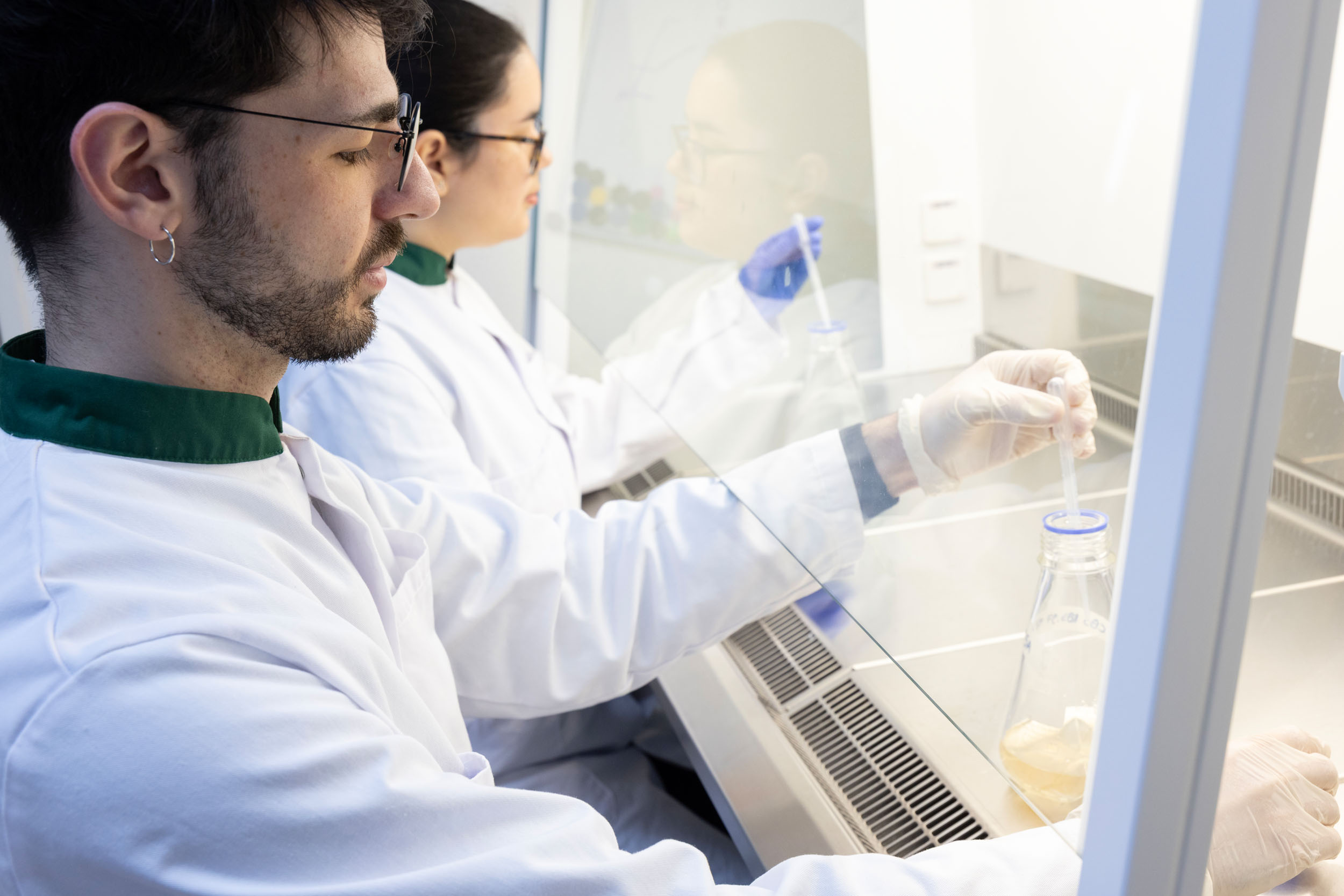

Traditionally, lactic acid is produced from refined sugars, such as corn and sugar beets. This makes it expensive and creates competition with food production. At LApure, we are investigating an alternative: producing lactic acid from low-quality biomass, such as cellulose-rich wastewater streams and agricultural waste streams. This allows us to utilize raw materials that would otherwise be lost and reduce the environmental impact of the production process.

A second focus is on PLA recycling. Thanks to technology from our partner TORWASH, PLA waste can be broken down into lactic acid. This offers the opportunity to reuse used PLA products as raw materials, creating a closed loop.

Optimizing downstream processing

The greatest challenge lies in downstream processing: purifying lactic acid to a quality suitable for new PLA production. In this project, we are investigating innovative methods to efficiently remove solids, water, and contaminants. These include techniques such as ion exchange, distillation and smart pretreatments with activated carbon. These steps are crucial for upgrading lactic acid from both residual flows and recycled PLA into polymer-grade lactic acid.

Collaboration between knowledge and practice

The project is a collaboration between:

- Nature’s Principles – developer of technology for lactic acid production from residual flows.

- TORWASH – specialist in hydrothermal recycling of PLA.

- MNEXT (Avans University of Applied Sciences) – with the Biobased Resources & Energy research group as project leader, responsible for conducting the purification tests.

Through this collaboration, we are combining knowledge from practice and research to develop feasible and scalable solutions.

Contribution to the circular economy

With LApure, we are taking an important step towards cost-efficient and sustainable production of bioplastics. By utilizing both new raw materials and recycling flows, we contribute to a circular value chain for PLA. This not only strengthens the biobased chemical industry in the Netherlands but also the international transition to a fossil-free future.

September 2025 until August 2026