What if I told you that there once existed substances and materials that were banned, forgotten, or lost? Not because they were dangerous or immoral, but because they were too advanced, too expensive, or simply not profitable.

Forgotten Traditions in Textiles and Metallurgy

|

In 18th-century Bengal, weavers created a fabric (Dhaka muslin) so fine that it was spoken of as “woven air.” It was made from a rare cotton plant that grew only along the banks of the Meghna River. The fibers were completely hand-spun and woven through sixteen complex steps. Producing a single thread could take weeks, and a single piece of cloth, months. Mughal emperors wore it. European aristocrats admired it, yet it alarmed the East India Company. Dhaka muslin did not fit their model of fast, cheap, and profitable production. Within a century, the knowledge was lost, and the cotton plant became extinct. A 2,000-year-old tradition disappeared. |

| A similar story is seen with Wootz steel, produced around 300 BCE in India. The steel was reinforced with microscopic structures we now recognize as carbon nanotubes, giving legendary Damascus swords their sharp, self-honing quality and exceptional durability. Metallurgists from the Deccan perfected iron and carbon in small clay crucibles, creating a microscopic lattice of cementite and pearlite. This gave the steel its characteristic watery pattern and a strength unmatched anywhere in the world for another thousand years. It was not magic: it was metallurgy at the highest level. Colonial interference disrupted local iron ore sources, crucibles were destroyed, and recipes forgotten. Even today, we can analyze the steel but cannot fully replicate it. The real loss wasn’t the alloy itself, it was the mastery behind it. |

|

Mastery and Memory

These stories are not just about textiles or metal, but about mastery and how fragile it is. How often do we exchange deep knowledge for convenience, craft for control, and precision for profit. Just as Dhaka muslin and Wootz steel were lost, we risk losing valuable techniques today if we focus solely on mass production and speed. Believing in the myth that newer is always better. In the sustainability sector, innovation is not only about new solutions but about memory. We no longer grow from local wisdom outward; we compress global systems downward. And in this top-down shift, we lose our connection to place, climate, material, and intent. We have learned to build with convenience in mind, without attention to climate, culture, or care.

It is not just about asking, “What is new?” but more importantly: “What is worth carrying forward?”

The Value of Natural Materials

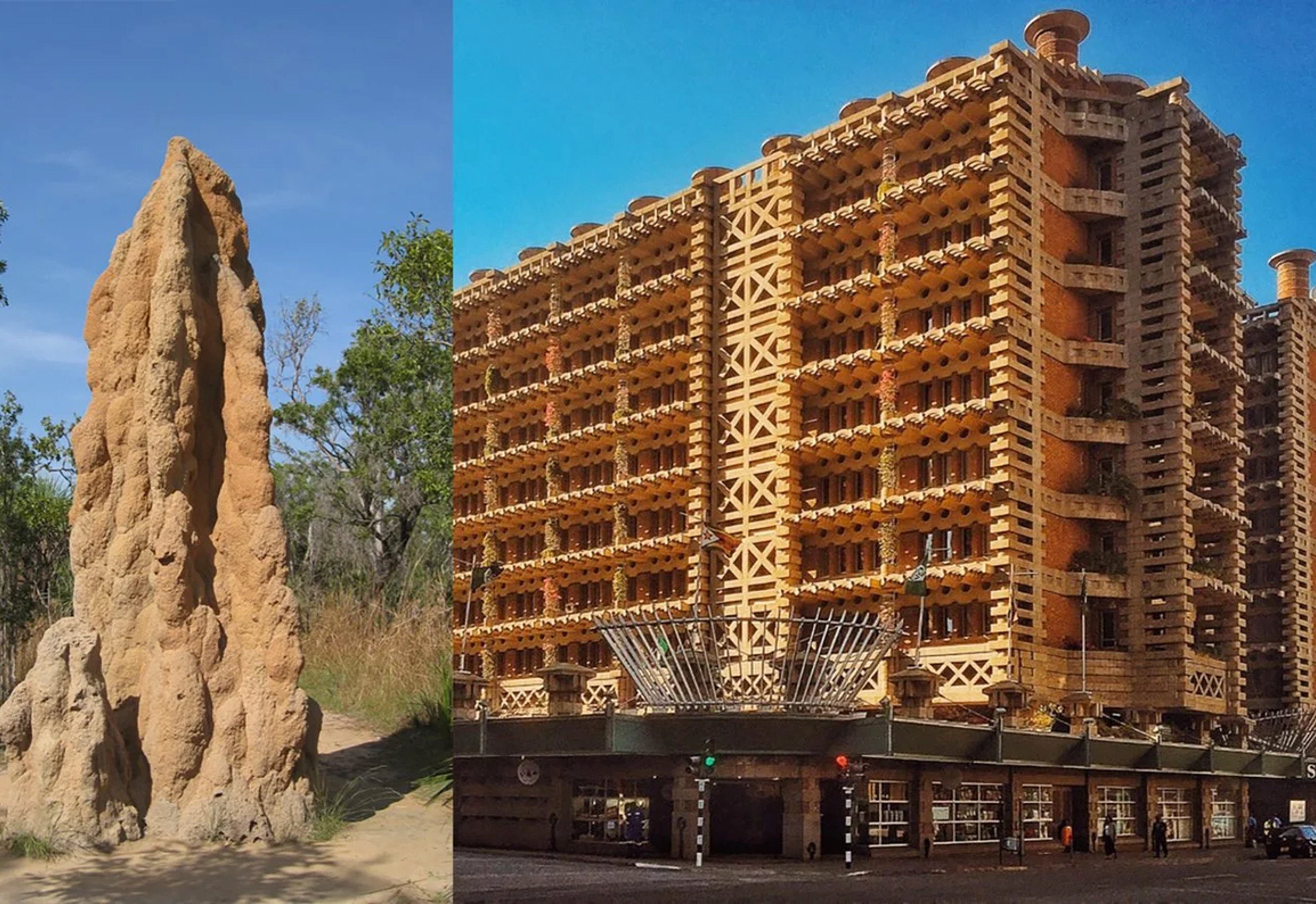

Consider modern cities: steel, glass, and concrete, cloned across continents. In theory sustainable, but in practice often brittle, energy-intensive, and lacking empathy. Buildings today are designed for speed, not for climate or connection to their surroundings. They resist nature, isolate, and separate; often at enormous ecological costs.

We have forgotten that building was once a technical, ecological, and cultural act. A building was a dialogue between a people and their land, made from what was available and shaped by what was needed. Every wall told a story about soil, climate, and people.

That is why natural materials deserve our attention. Take rammed earth: soil, pressure, and patience. No cement, no steel, yet it acts like a thermal battery that stores and releases heat, regulates humidity, dampens sound, is fire resistant, and produces almost no embodied CO₂. Structurally, rammed earth walls transfer forces through granular friction between billions of particles. This is not a primitive technique; this is material intelligence.

From the Great Wall of China to the adobe mosques of Mali, from Ladakh to Provence, earth has always been a teacher. Those who listen learn to build in ways that unite climate, culture, and technique.

Structural Genius

Stepwells Gujurat

Stepwells Gujurat

The genius of ancient builders extends beyond materials to form and structure. Consider the stepwells of Gujarat: intelligently designed to conserve water, cool air, and distribute load. Incan walls in Cusco move with earthquakes instead of resisting them. Nubian vaults, bamboo trusses, and Gothic cathedrals operate on intuitive calculation, experience, and time: not formulas.

Why have we abandoned this knowledge?

Because our standards changed: building regulations, fear of the unknown, financial systems rewarding speed over sustainability. We started to associate natural materials and ancient methods with primitiveness, while they contain answers to some of our most advanced design questions.

As with Wootz steel and Dhaka muslin: we melted wisdom into something uniform, predictable, and forgettable.

Rediscovery and Integration

The good news: we are beginning to remember. Architects and engineers are seeking dialogue between traditional techniques and modern tools. Parametric design simulates airflow, daylight, and load distribution; the very lessons ancient builders learned through time and observation.

Digital models help design climate-responsive rammed earth walls and low-carbon housing using local materials and traditional geometries. It is not about nostalgia but integration. We do not need to choose between tradition and innovation; we simply must stop treating them as opposites.

So maybe the question isn’t: “How do we build better?”

But rather: “How do we remember better?”

A call for change

We live in a time of climate collapse, housing crises, and disconnection. Yet beneath our feet and in our archives lies a whole library of genius. Sometimes the future of innovation begins precisely where the forge has cooled. And sometimes the most advanced solutions… are the ones we have forgotten how to make.

So how do we prevent losing knowledge before we understand the science behind it?