Within the European BRIC project, research institutions, companies, and governments collaborated to develop new sustainable biobased construction materials. In addition to development, the partners investigated how to expedite bringing these materials to the market. This is a crucial task, as the construction sector in Europe is responsible for 30% of greenhouse gas emissions, and globally one-third of raw material extraction is dedicated to the construction sector. Sustainable products and reuse are therefore not just a luxury but a necessity.

Conundrum

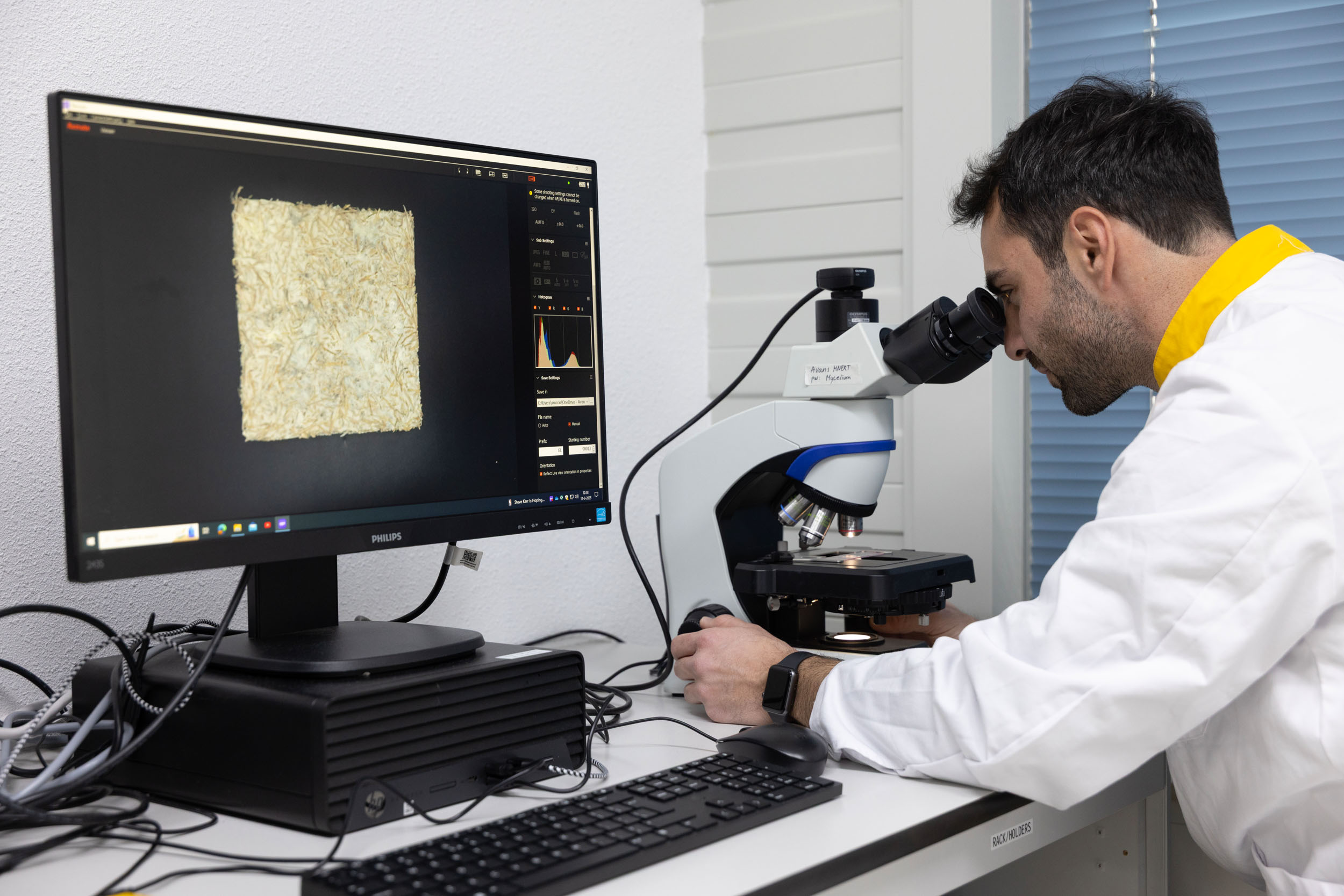

Lennart Zoeter from the Biobased Building research group faced a tough challenge. The question of whether he could mechanically recycle thermoset composites gave him quite a headache. “Many companies and research institutions have already tried something like this,” he explains. “That sometimes made it feel like an impossible task, especially during the first half of the project. I had to do a lot of research.” If he had been asked to create something new from thermoplastic composites, it would have been much easier because they can be melted. This is not the case with thermoset composites. When heated, thermosets turn into gases. “It just disappears. That’s what makes it so difficult,” says Zoeter.

Adjusting the recipe

Eventually, he managed to apply a recycling method for a so-called BMC composite. This composite consists of resin, a filler (calcium carbonate), and a fiber. The recipe lends itself to modification. Zoeter replaced calcite with crushed thermoset (bio)composite. This allowed it to be heated and crushed. “That’s a win, but it’s not a solution that works indefinitely. Each time you crush it, the proportion of resin increases. This changes the properties. So, you don’t get back the original composite but something else.”

And when the properties of a product change, you have to apply it differently. “During our tests, the strength of the product did not decrease, but it became lighter and less rigid. That has consequences. It is then no longer suitable for all applications.” Zoeter also had to adjust his goals in the project. The original goal was to develop a tabletop, but it eventually became floor tiles and wall sockets.

Biobased Pavilion

The floor tile module was present at the end of October during the Dutch Design Week in a biobased pavilion designed by a colleague researcher from Eindhoven University of Technology. Thousands of people walked over the floor to enter. There, they also saw Zoeter’s wall sockets. “It was a beautiful conclusion to the project we worked on for four years.”

Although he is glad it succeeded, Zoeter doubts whether products made from thermoset composites will quickly appear in stores. “The process is difficult to make profitable because you have to crush it. That’s not an easy task. The composites are extremely hard. This makes it cheaper to work with materials that have not been used before,” he says. “Moreover, calcite is cheap and resin is expensive. In an ideal situation, you recover the resin chemically because that’s where your economic value is. Now, you replace the cheap material with recyclate.”

In the four-year OPZuid project, HZ collaborated with institutions such as Eindhoven University of Technology, Avans University of Applied Sciences, a major contractor like VolkerWessels, and several entrepreneurs in the biobased sector.