The project is an initiative of two Centres of Expertise at Avans University of Applied Sciences – MNEXT and Perspective in Health – in collaboration with the AI company Biotactical, based in Leiden. Together, they are building smart technologies to give the biobased industry a significant boost.

Smarter Control of Growth Processes

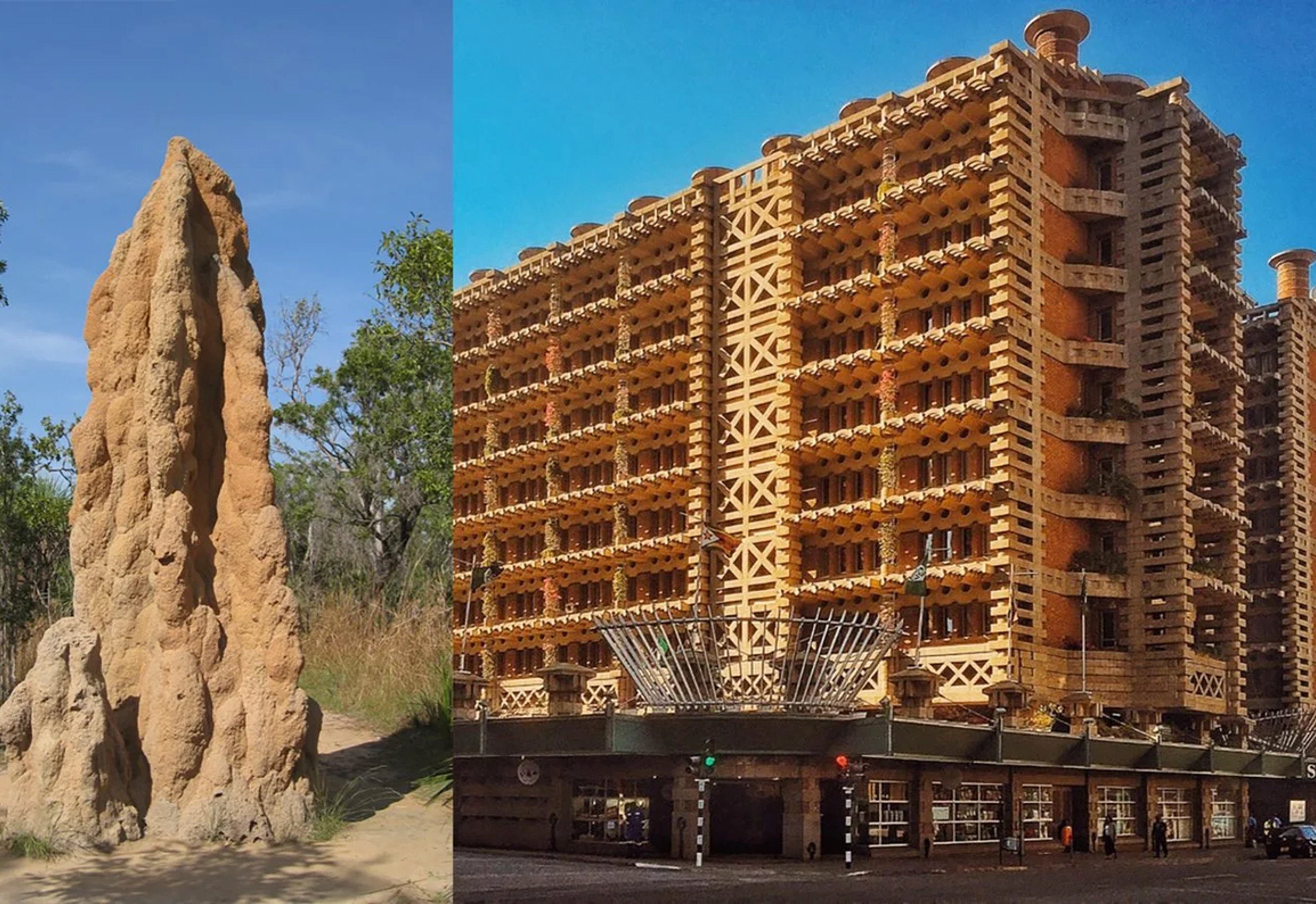

FungAI focuses on automating and monitoring the growth process of mycelium materials, which are increasingly used as eco-friendly alternatives to materials like Styrofoam, leather, or wood. The challenge? Production is still largely manual and based on fixed time intervals, which makes scaling difficult.

“Mycelium is a promising natural material, but the way we currently produce it is too static,” says Stefano Roccio, researcher and project leader at MNEXT. “With AI, we can make that process smarter, understand it better, and optimize it.”

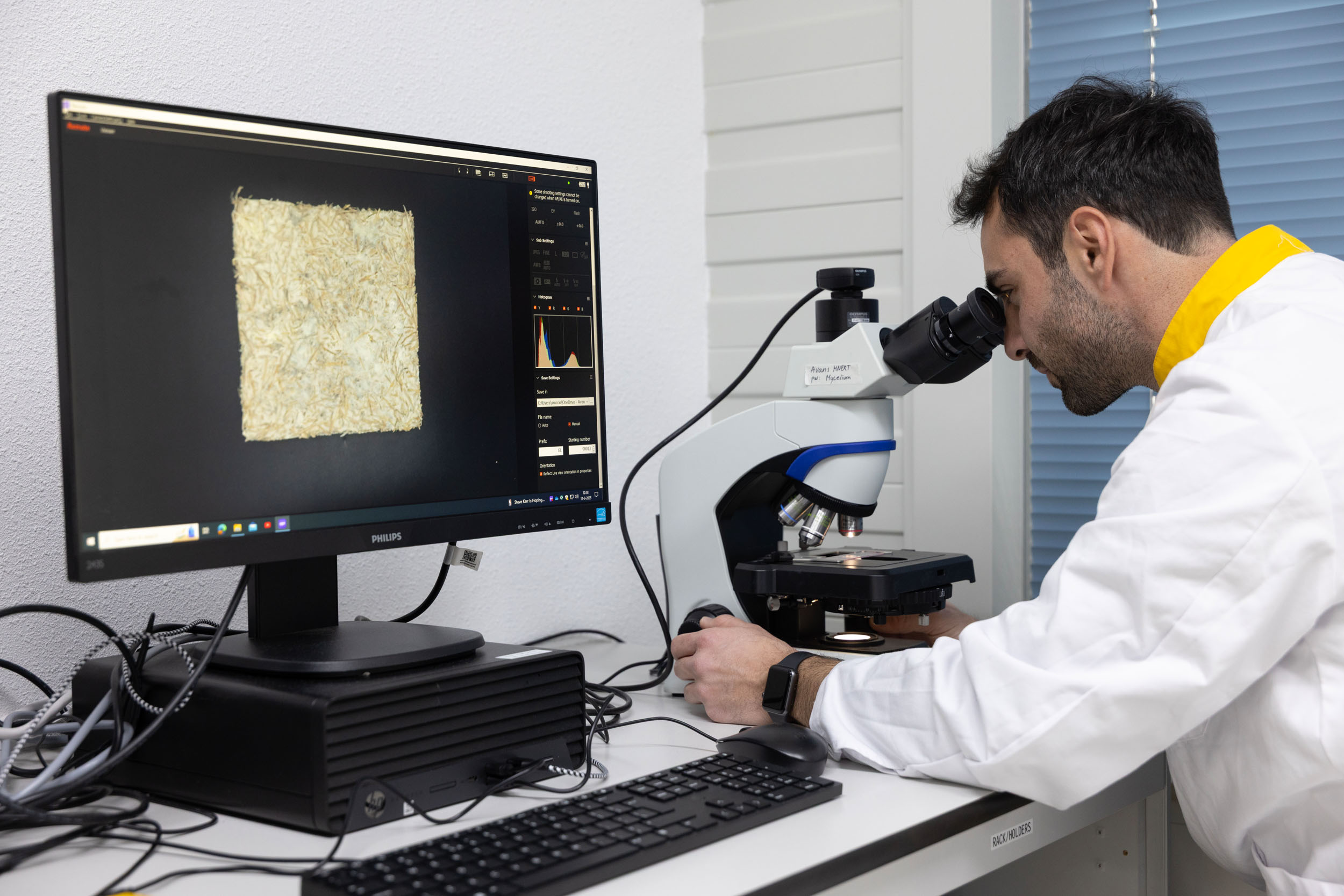

Image Recognition and Learning from Feedback

In practice, mycelium samples are often placed in an incubation chamber for a fixed number of days, followed by manual inspection – a time-consuming and inaccurate process. After all, fungi don’t follow a clock.

That’s why FungAI developed an AI-powered system that continuously captures images using a simple photo box. Based on those images, the model automatically assesses whether a sample is undergrown, optimally grown, or overgrown.

“Thanks to user feedback, the system keeps getting smarter – we call that guided learning,” Stefano explains. “The more it’s used, the better it learns. That makes large-scale, sustainable production much more feasible.”

Two Paths to Smarter Production

The project explores two routes toward smarter production, each with its own focus:

1: Determining the Optimal Harvest Moment

This track focuses on biocomposites: strong, natural materials that can, for example, replace Styrofoam. The team is investigating how to predict when such material is ready to be harvested – not based on a fixed time span, but on visual characteristics like color or texture, linked to physical properties such as strength or density. This ensures harvesting always happens at the ideal moment – not too early, not too late.

2: Fungal Identification Without DNA Testing

Anyone using fungi for production needs to know what species they are working with. Currently, this is usually done through DNA testing – reliable but slow and expensive. That’s why FungAI is also developing an AI model that identifies fungal species based on their growth patterns. How does a species develop in a petri dish? How fast does it grow? What does the surface look like? By analyzing thousands of images, a digital ‘fingerprint’ is created to automatically identify species.

The AI model for biocomposites is already operational. The more complex model for species recognition is expected to be completed by the end of June 2025.

Collaboration as a Key to Success

FungAI’s strength lies in the combination of knowledge and practice. MNEXT focuses on material development, Perspective in Health brings in AI expertise, and Biotactical translates it all into working AI models.

Krishna Sheombar Sing from Biotactical guided the AI development from their side. “My role was to keep the AI part simple and effective. That way, we were able to make significant progress within a short time frame,” he explains. “What stood out to me most was how pragmatic the collaboration with Avans was. No endless meetings—just getting started. That really works.”

Margriet van Gestel, Professor of Generative AI at the Centre of Expertise Perspectief in Gezondheid, is also enthusiastic about the collaboration: “We successfully retrained existing AI models on something completely different: fungi. It shows how flexible AI can be. When you bring the right people together, you can really move fast.”

Future: A System with Great Potential

What makes this project special is its broad applicability. The system can be retrained for other sectors – from construction materials to leather substitutes and even food applications. That makes the possibilities for the future endless, and this is just the beginning. Follow-up projects are already being prepared, once again involving MNEXT, Perspective in Health, and Biotactical.

“Our ultimate goal is a fully automated system,” says Stefano. “Imagine robotic arms that can make real-time adjustments inside the incubator. Sounds futuristic? Maybe. But it’s coming faster than you think.”

Interested in Collaboration?

Do you see opportunities to collaborate on this topic? Get in touch with Stefano Roccio, researcher and project leader at MNEXT.

FungAI is funded by the Pre-Seed Fund of Avans University of Applied Sciences, which supports small-scale, multidisciplinary research projects and helps lay the groundwork for larger collaborations and innovations.