This experiment is part of a broader research effort within the MycEoLA project, which investigates the lifespan and end-of-life of mycelium biocomposites. While some tests are being conducted under controlled lab conditions — where mycelium biocomposites are biodegraded in compost and variables tightly monitored — the experiment at the Living Greenlab offers a raw, outdoor setting with natural soil, microorganisms, and weather influences. “We’re testing the real-life biodegradability of mycelium biocomposites,” says Paula, who’s doing an internship at MNEXT. “People assume it’s biodegradable because it’s made from natural ingredients like fibres and fungi. But no thorough assessment of how the material breaks down in real soil has been done. Until now!”

Simple approach, major implications

Paula explains the basics of the research that’s being conducted: “we wanted to keep it simple; just place the different biocomposites in the ground and observe what happens.” To do this, four variations of the rapeseed straw and mycelium biocomposites have been placed directly into soil; both coated and uncoated, and in two forms: foam and heat-pressed boards. By comparing these variations, the team hopes to better understand how structure and surface treatment affect biodegradation.

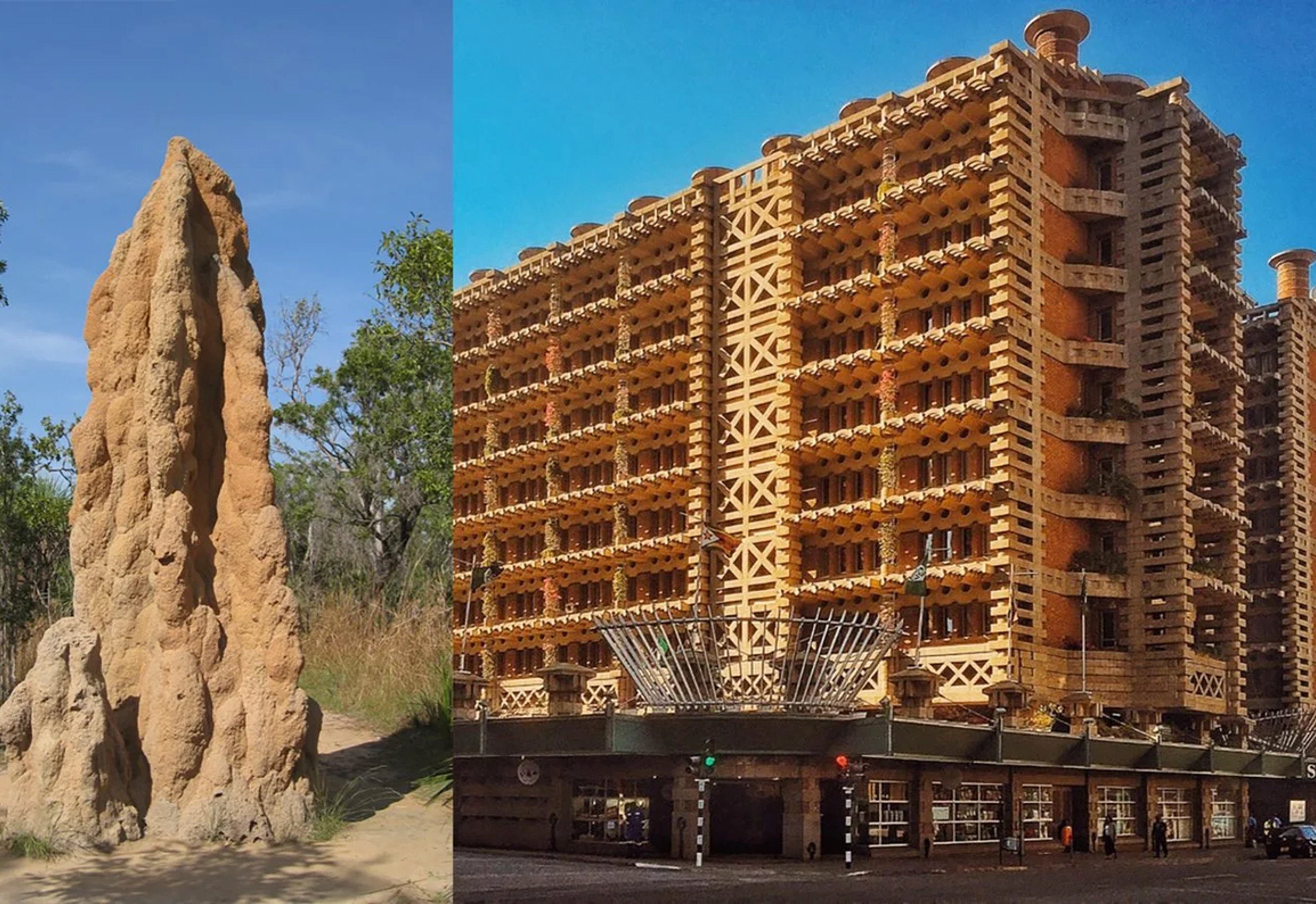

But simplicity doesn’t mean lack of impact. The implications of their findings could reshape how we think about sustainable construction materials. The construction sector plays a major role in global environmental impact. In Europe alone, it accounts for 38% of all waste, while globally it drives half of all natural resource extraction and nearly 39% of CO₂ emissions. These figures underline the urgent need to move away from conventional materials like concrete and EPS insulation and explore sustainable alternatives. Mycelium could offer a promising solution. “If the material really biodegrades in soil,” Fran, project leader of MycEoLa and researcher Biobased Construction at MNEXT adds, “you’re talking about a building component that could be made from agricultural waste, used in construction, and later returned to the earth without pollution. That’s the ideal of circularity.”

Challenging assumptions about biobased materials

Before we get to the point of mycelium biocomposites taking over the construction industry, some assumptions need to be challenged. Paula points out a key misconception: “Just because something is biobased doesn’t mean it will break down easily in the environment. There’s a real need for long-term studies that confirm how these materials behave during their lifespan and at the end of their life.” Her current experiment runs for twenty weeks — the length of her internship — while the actual biodegradation of mycelium biocomposites can take three to five months. “In contrast, many building solutions that are currently widely used — like EPS or mineral wool — aren’t circular,” says Fran. “Once they’ve been used, there’s not much you can do with them. They may last a long time, but at the end of their life, they often end up in landfills where they stay for decades, polluting the soil.”

A step toward change

The experiment may be small in scale, but it plays a vital role in building the evidence base needed to shift practices in the construction sector. “Hopefully, our work gives professionals a better idea of how mycelium behaves and what its limitations and advantages are,” Paula concludes.

For now, the samples remain buried — quietly decomposing, or not. And with every passing week, we get closer to knowing the potential of a material that could help reshape the future of the construction industry.