MNEXT (Avans Hogeschool) werkt binnen ImPHAct! samen met Paques Biomaterials, Looop en Cargill. Een mooie samenwerking waarbij MNEXT verantwoordelijk is voor project management, uitvoeren van laboratorium werkzaamheden, data analyse en communicatie.

PHA produceren

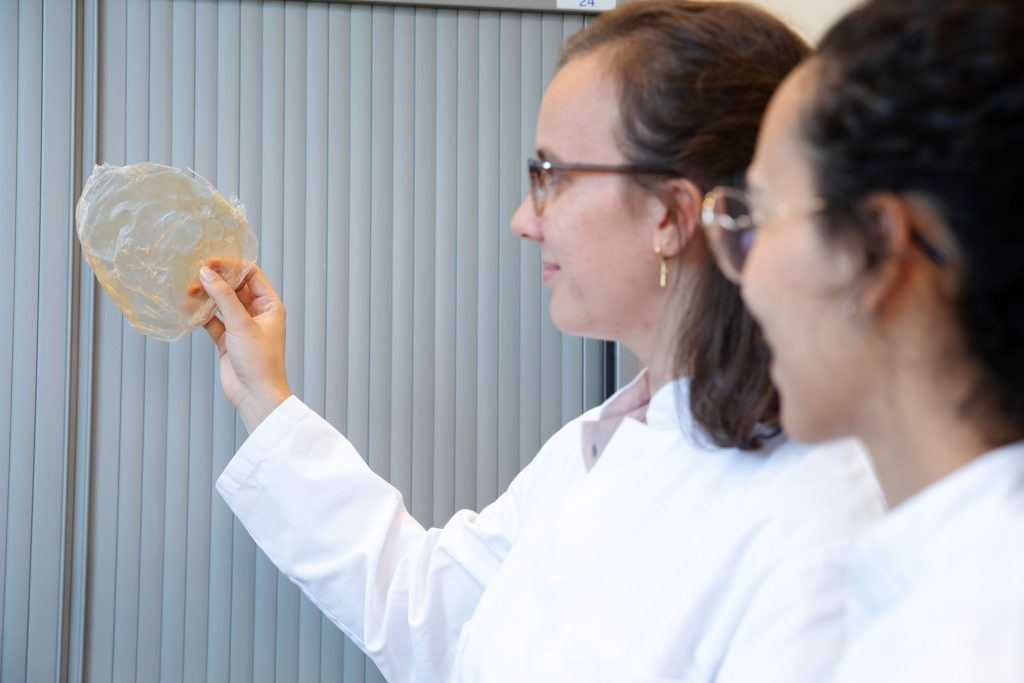

Nu denk je misschien: Hoe maken ze dan PHA vanuit reststromen? De projectleider Mithyzi Andrade Leal legt uit: “Bacteriën gebruiken organische stoffen zoals suikers en zetmeel die in het afvalwater zitten voor het maken van PHA. Dit doen ze door de organische stoffen eerst om te zetten in zogenoemde vluchtige vetzuren. Deze vluchtige vetzuren kunnen vervolgens worden omgezet in PHA. Dit PHA wordt weer door de bacteriën in hun cel opgeslagen als reserve energiebron. Als de bacteriën vol zitten met PHA, dan halen we het PHA uit de bacteriën”, zegt Mithyzi.

Bioplastic moet in de toekomst het traditionele plastic vervangen en dan met name van producten waarbij biologische afbraak gewenst is. Denk hierbij bijvoorbeeld aan visdobbers, die blijven vaak onbedoeld achter in de natuur.

Voorspellen en stabiliseren

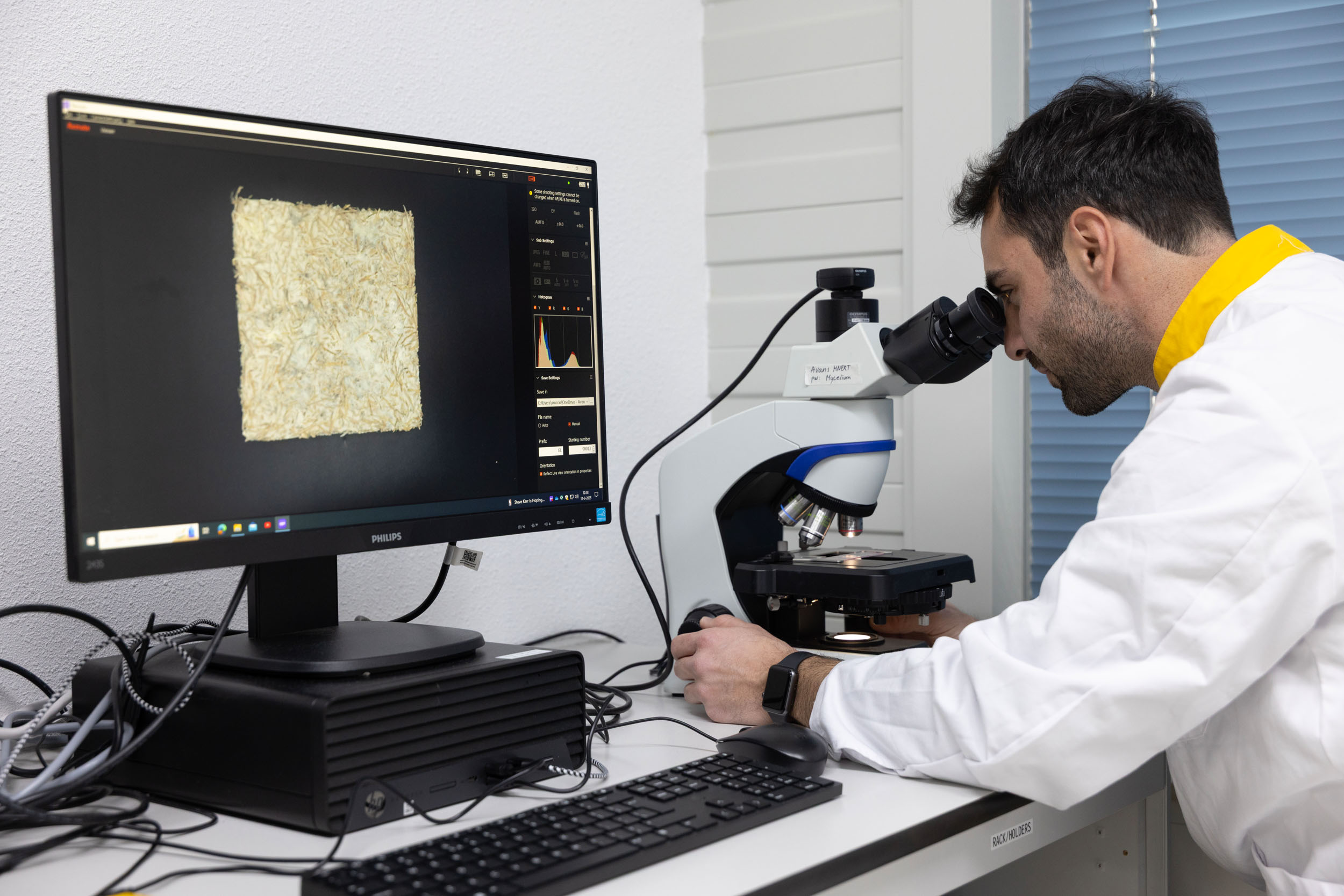

Ondanks dat er al heel veel kennis is over de productie van PHA zijn er nog steeds stappen die verbetert kunnen worden. Een van deze stappen is het omzetten van de organische stoffen in het afvalwater in vluchtige vetzuren zoals azijnzuur en propionzuur. “We willen dit proces beter kunnen voorspellen zodat we beter weten welke vluchtige vetzuren er worden geproduceerd. Dit zorgt dan weer voor een beter voorspelbare en stabiele productie van PHA”, zegt Mithyzi. Hoe pakken ze dat aan? “We gaan een innovatief voorspellend model voor de productie van vluchtige vetzuren ontwikkelen waarbij biologische en chemische gegevens worden geïntegreerd. We doen dit door te kijken naar de verschillende factoren die belangrijk zijn bij de productie van vluchtige vetzuren zoals pH, temperatuur en tijd. De verzamelde gegevens gebruiken we om het model te maken. We maken hierbij ook gebruik van de gegevens die we verzameld hebben in voorgaande projecten.”

Inmiddels zijn de partners al volop aan de slag. Juni 2025 is de verwachte einddatum. Wil je graag op de hoogte blijven van de voortgang van dit project? Of wil je meer informatie? Neem dan contact op met de projectleider Mithyzi Andrade Leal, m.andradeleal@avans.nl.