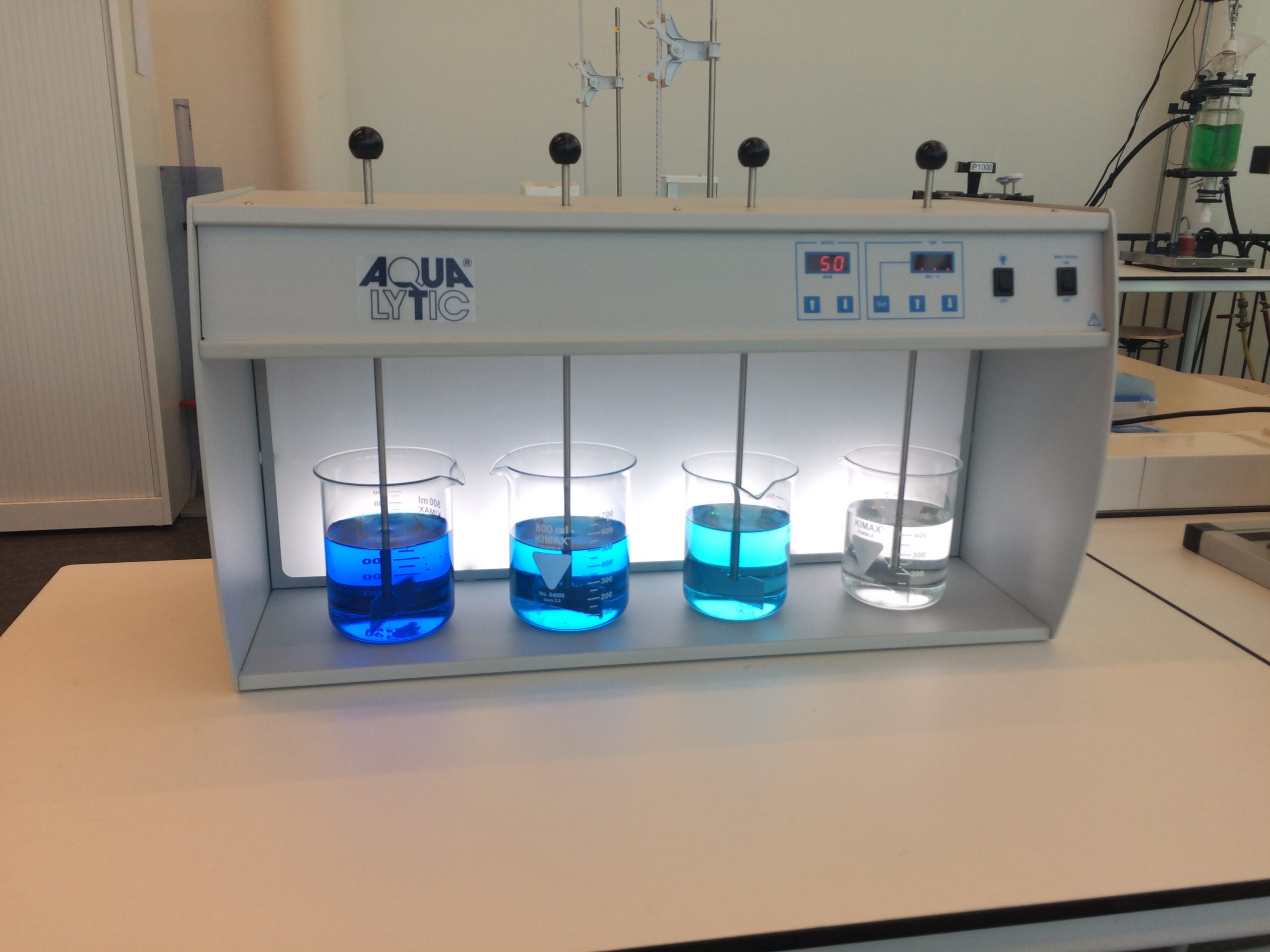

In this collaborative project it is investigated whether and how bioflocculants can be made from potato waste and how they work in comparison with the regularly used (acrylamide) polyelectrolytes. Flocculation is used in water purification to remove substances from water. This process is used in the purification of ground and surface water to produce drinking water as well as in the purification of sewage.

Win-win

A possible alternative is the production of flocculants from starch rich (residual) streams from the potato processing / starch processing industry, such as Novidon. These residual streams can now cause a considerable burden for sewage treatment plants. Using the residual flows for the production of a biobased alternative to synthetic polyelectrolytes can therefore result in a win-win situation. The starch waste flow is partially converted into a valuable product, while at the same time the burden (and therefore costs) for water purification would decrease.

What is Flocculation?

Flocculation is an essential step in the water purification process. It is a process in which particles adhere to each other in a loose structure. A well-known example is the formation of snowflakes by joining snow crystals. The structure of flakes is quite easy to break, because the bond between the molecules and groups of molecules is not that strong.

20200901 until 20210801