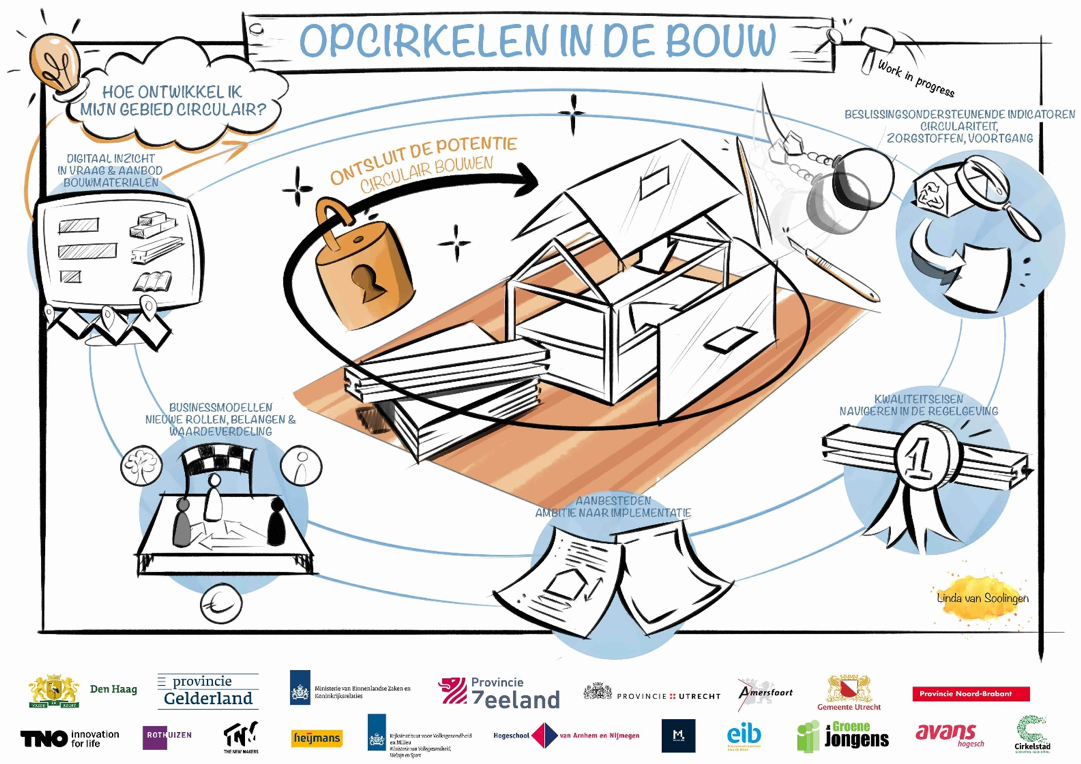

These insights are usually lacking (with a few exceptions, such as analyzes for Amsterdam and Amersfoort) and therefore there is not much insight into the identification of the best opportunities and their impact. To make informed decisions, policymakers need answers to questions such as:

– How much demolition material will be released in the coming years? And how much material is needed for the planned construction assignment?

– How much of this demolition material can be used in a high-quality manner? Which technologies are suitable for this? How can high-quality reuse be increased?

– What is the scale on which circular construction and the use of secondary materials are efficient (economic / environmental)?

– What is the impact of circular construction on construction logistics in cities? The activities in this work package aim to provide these insights and thus provide policymakers and companies with answers to the above questions.

In the project we switch between an overarching, generic level that can make statements about an integrated approach for the built environment for the long term and a specific level that offers the possibilities for validation and realization of the action perspective. We focus on facades (skin – from the 6s model, see Figure 2). The facade is interesting from the perspective of the energy transition and makes it possible to address the full breadth of the circular economy (life extension, reuse, recycling).

Within the broader context of the project, Avans is involved in WP3: WP3 is developing a process tested in and against practice to arrive at business models for the circular use of the materials and components in the facade. The research highlights new forms of value creation, collaboration / organization and preconditions to arrive at a circular business case. Taking into account the impact of circular facade techniques from WP1 and WP2 and (development in) standards, legislation and regulations, tendering processes and the labor market (WP4). Where possible, general lessons learned are drawn up.

Companies are actively involved in the research and learn from the research approach in which a process created within the HOPLA project is deployed. Companies and governments can use the results to define a better approach for their circular projects.

20191203 until 20211203