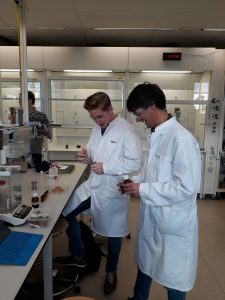

Dutch onion cultivation and processing produces approx. 30,000 tons of onion skins per year, of which approx. 20,000 tons in the vicinity of Kruiningen. This large quantity makes it possible to process the onion skin residual flow centrally. Onion skins have a high content of quercetin, which can be used as a food supplement, anti-oxidant and natural coloring agent. Together with the HOA, onion processors Monie Nieuwdorp BV and Mol Fresh Food BV and the educational institutions Hogeschool Zeeland and Avans Hogeschool (Center of Expertise Biobased Economy), research has been conducted into the technical and economic feasibility of processing onion skins. This project is partly financed by the Province of Zeeland.

Indeed…

The research shows that the refining of onion skins is certainly technically and economically feasible. A process has been developed for the recovery of quercetin in which a high purity is already achieved with a few simple separation steps. Due to the central availability, logistics for the supply of onion skins is not expensive. Finally, quercetin is already known as a dietary supplement. So there is an existing market that will grow in the future. The quercetin in these products can be replaced one-to-one by quercetin from onion skins.

Benefits

- Extra customer for onion skins from onion processors

- Circular and sustainable use of residual electricity

- Environmentally friendly process without additional chemicals

- Well-known product in the market as a dietary supplement

Near future

- Further development and upscaling of the refining process to production scale

- Produce quercetin from onion skins for market research and testing applications

20180101 until 20191231