Climate change and the depletion of resources in the world are recognized as one of the greatest societal challenges. The construction industry alone is responsible for 40% of global raw material consumption. In addition, waste from the construction and demolition sector is considered to be one of the largest residual materials in the EU.

Mycelium as a natural alternative

Mycelium is the “root network” of mushrooms, which acts as a natural glue to bind biomass. Various organic residual flows such as straw, sawdust or other agricultural waste can be used as a nutrient medium. Mycelium composites are innovative products, with intrinsic properties that attract the attention of architects, designers and industrial companies. Both mycelial foam and sheet material have the potential to replace conventional toxic materials.

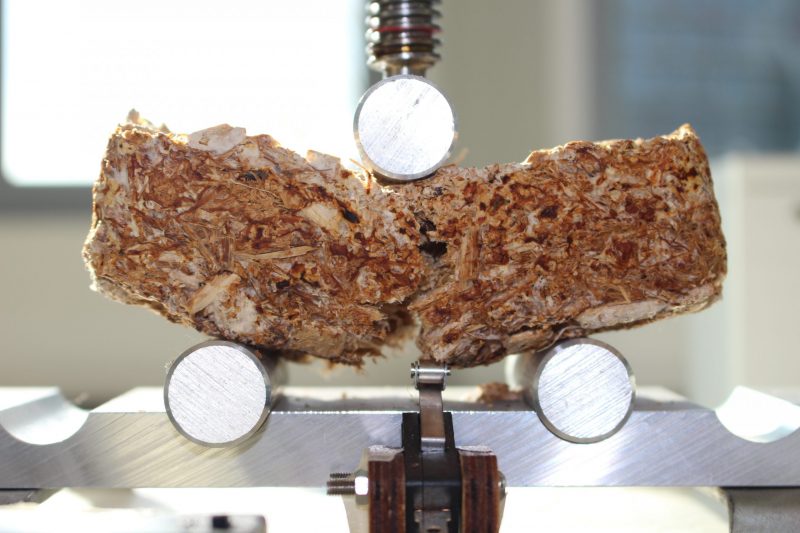

Heat process

The mechanical properties of these mycelial products are influenced by their manufacturing process. For example, it has been found that the flexural and tensile strength of hot-pressed mycelial plates is higher. The heat pressing process with regard to mycelium plates must be further developed in terms of temperature, pressure and duration of pressing.

Research questions

Project partners KNN Cellulose BV, Fungalogic and V8 Architecten approached CoE BBE to jointly carry out this research into mycelium plates. The interest of each of the partners is focused on different aspects of mycelial plates, which can be summarized in the following questions:

The following research questions are addressed:

- Which heat press process is the most optimal for producing sheet materials?

- Which heat press parameters (considering temperature, pressure and duration) are the most optimal to produce mycelial plates?

- Can cellulose and hemp fibers be combined to form a stronger sheet material?

20200131 until 20201231