In 2017, a research question arose from tomato growers. CoE BBE was approached with the question whether enzymes from the tomato leaves could be used to “purify” the drain water (the excess nutrient water that has not been absorbed by the crop) from the greenhouse. The grower could generate additional income in this way. The research project has now been completed and major steps have been taken.

Han van Kasteren, professor at CoE BBE, is satisfied with the project results.

The case: Tomato growers use crop protection products just like other gardeners. These rinse away with the drain water. The environmental requirements for these products will become stricter in the coming years and growers are also constantly looking for new ways to save money and to add value to their residual flows.

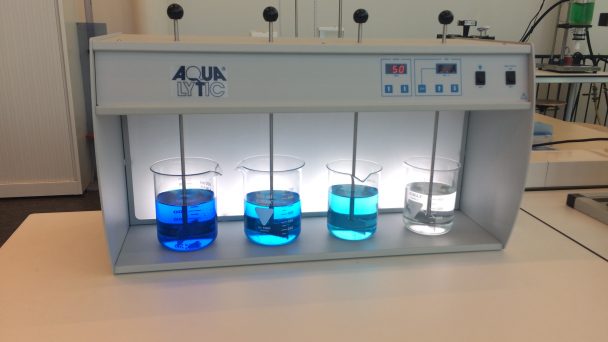

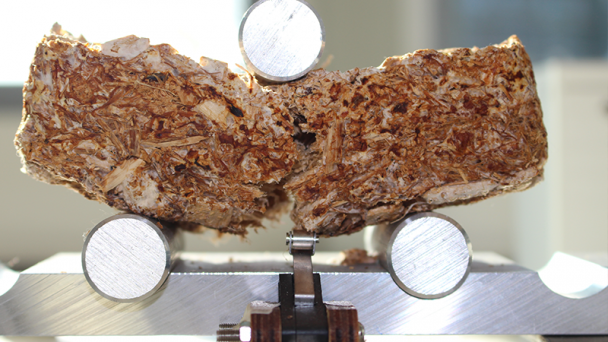

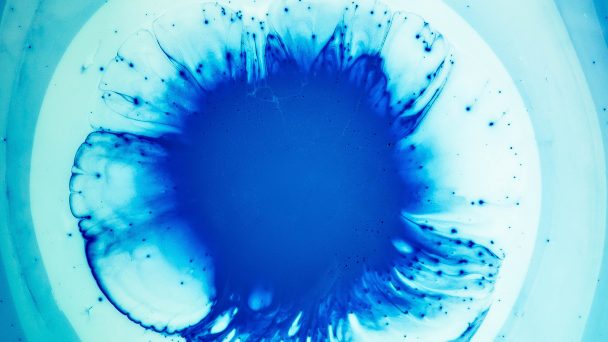

And that is where the question arises: Can we purify the “polluted” irrigation water with tomato leaves? “Certain types of enzymes have the property that they can break down crop protection agents. Last autumn we collected the tomato leaves and extracted the enzymes with a specially developed press. In the laboratory we started working on various tests. This resulted in the following conclusions: There are indeed active enzymes in tomato leaf extract. And these enzymes still work after they have been stored for a longer period, ”says Han van Kasteren.

But does the enzyme work to such an extent that the grower can use it for the purification of drain water? Unfortunately, the last point from the study could not be proven. “Because there is virtually no difference in the degree of degradation of the crop protection products between whether or not to use the tomato leaf extract.” The stability of the crop protection product appears to play an important role in this.

The project and research have now been completed but the problem has not yet been resolved. “There are enough questions to start a new investigation. For example, whether the enzyme works with more stable crop protection products and whether there are other applications. Then we would have to start a new project. And that decision has not yet been made. ”

The research was based on the study conducted by Stichting Innovatie Glastuinbouw (SIGN) into the market interest in simple enzyme extracts from greenhouse horticulture residues. SIGN works together with two SME partners, Duijvestijn Tomaten and Lans Zeeland. Together they approached CoE BBE.

Lokaal opwekken, lokaal gebruiken

Deze gaan we nog vaak terugzien

Recycling Water Bottles into Circular Sports Products

FermiChem

Protein of Columbus

BIO-CAPPP

Energy Education

BIO-CAPPP

GESCHIKT: energy transition on business parks

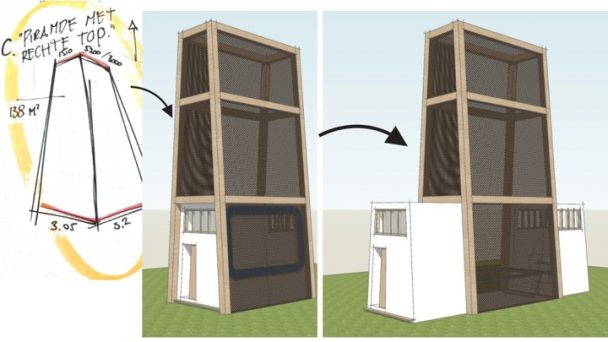

Rapid Renewable Materials: the next step in sustainable construction.

Mycelium on Board

From orange waste to a green future

Blueprint of fungal genomes

BioGov.net

Water-resistant mycelium composites

Sustainable Particle Board

Circular Emergency Shelters

FACET

Totally Nuts: Circular Biobased Thermosets from Cashew Nutshells

Biodegradation Coatings Stahl

Green Hub: Information hub value chains green residual flows

Acceleration of nature-inclusive area development

Reflow

Biobased Insulation – Lifespan Determination (BILD)

Setting up and performing biodiesel trials in a coaster ship

Mythic

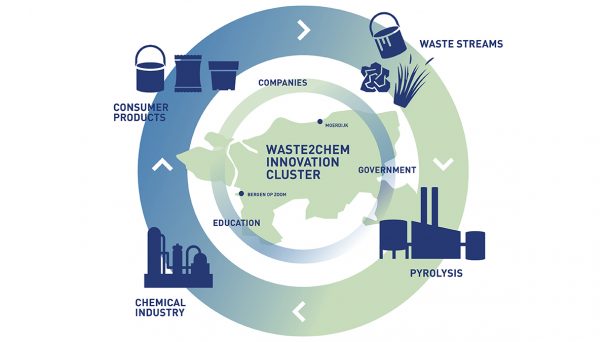

PyroCHEM: Waste2Chem Innovation Cluster

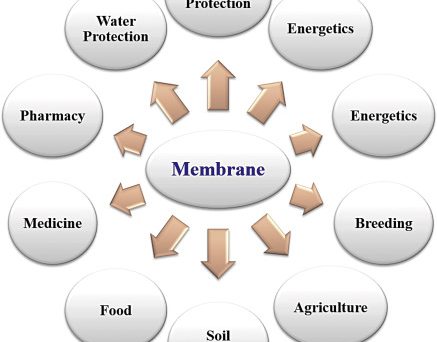

Membrane Technologies

Flestic

Direct extrusion of PHA-rich biomass

Production of bioplastics from residual streams (WoW! Capitalisation)

Powering Agrifood

Smart Circular Bridge

Fungal Colourants

Learning Network Biobuilders

Orange in the Sea

Amino Acids!

Building on Mycelium

Follow-up S4G

Colour Application Centre

Making disposables disposable

Making shipping more sustainable (Russia – Benelux)

Zircular Seaweed food

Extraction of pectins from onion skins

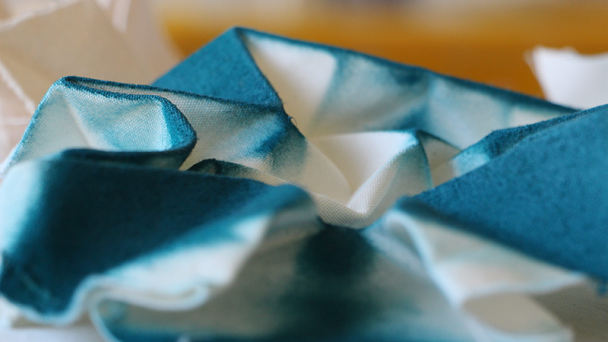

Growing Leather

Learning Community Renewable fuels

PHA accumulation capacity of Sewage Treatment Plant

NACO – Zero Waste Collective Oosterhout

Bio Iso (RAAK MKB)

Design with RRM (rapidly renewable materials)

Resin biodegradation

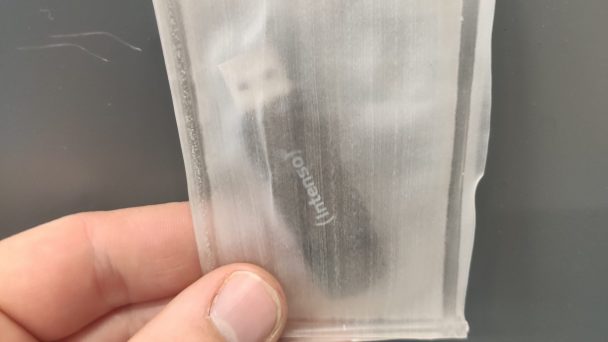

Biobased gadgets

Biobased foam

Biobased flocculants for water purification

Viberscrete – biobased concrete

Innovation Traineeships

Building light

BioADD

CurCol

Learning community

Professors’ platform Biobased Economy

Porter’s lodge Delfland

Smart Circular Bridge

Biobased, circular Christmas bauble with packaging

Mycelium boards

Coloring Mycelium

Back to the Materials of the Future

National Biobased Database

Structural Health in Biobased Constructions

Beauti-Fully Biobased Fibers

Coffee Silverskin Biomass Utilization

Sustainable solid biofuels

Biobonding: Improved biocomposites

ZCORE (from Seaweed to COating Resin applications)

Cashing cashew

Material research for 3D printing

Seaweed Sterols

Onion deserves more

Circling in construction

Biomass flows in the province of South Holland

Circular Bio-based Construction Industry (CBCI)

Biodegradability of biopolymer and biopolymer composites

BBM+

Opportunities for composting in Brazil

Stadsjutters Breda

Innovation tables

Tomatozyme

MAA’s from algae

Sensor wise Biobased

Pyrolysis Experimental Garden South

Grassification

REFAWOOD

Valuable ONION

Biobased Network

Living Lab Biobased Brazil

Biopolymer Application Center

Borderless Biobased Education

Living Colors

Mycelium

BioCOLOUR

BioCannDo

Blue Chain

WOW!

Green Growth

Biobased Challenge

Biobased bridge

Pure Nature: 100% Biobased

National Biobased Knowledge Network