The Pyrolysis Living Lab is there to stimulate and research the developments and applications with pyrolysis.

What exactly can you do with pyrolysis?

Pyrolysis is a thermochemical conversion technology that is suitable for a wide range of residues and renewable raw materials, varying from different types of biomass and biomass residual flows to waste flows such as mixed or contaminated plastics and car tires. In the Netherlands, this involves 2.5 million tonnes / year of residual flows that are currently incinerated or recycled at a low level, for which pyrolysis could be an attractive processing method. Because pyrolysis can convert residual flows from all kinds of sectors, including agro-food, (bio) chemistry and recycling, into liquid (transport) fuels or raw material for the chemical industry, it is pre-eminently a technology that connects different sectors. Due to the large presence of both the chemical and agro-food sector in the south of the Netherlands, pyrolysis offers excellent opportunities for creating new value chains between or within these sectors. The challenge to fully utilize the potential of pyrolysis and to make pyrolysis a commercially feasible process, however, lies in being able to convert the lowest possible quality raw material into the highest possible quality product.

What do they want to achieve with this project?

The aim of the Pyrolysis Proeftuin Zuid-Nederland project is to demonstrate approximately 30 unique value chains with pyrolysis technology by means of 4 different pyrolysis technologies and an open innovation strategy, whereby residual flows offered in the South of the Netherlands are converted into a product that is as high-quality as possible: (transport- ) fuels and raw materials for the regional industry, which further processes them into end products. In this way, cross-sectoral value chains can be created.

Business cases will be validated within the project, so that commercial pyrolysis installations can eventually be rolled out in the Southern Netherlands and beyond. It is precisely by combining different pyrolysis technologies in one project that a reliable overview can be obtained of the spectrum of raw materials and end products for which pyrolysis can offer commercially feasible solutions. This living lab project will set up the cluster and demonstrate the business case for the technology by means of a demonstration of value chains based on pyrolysis, so that the cluster can then operate independently, and pyrolysis can be rolled out within the Southern Netherlands and beyond.

Lokaal opwekken, lokaal gebruiken

Deze gaan we nog vaak terugzien

Recycling Water Bottles into Circular Sports Products

FermiChem

Protein of Columbus

BIO-CAPPP

Energy Education

BIO-CAPPP

GESCHIKT: energy transition on business parks

Rapid Renewable Materials: the next step in sustainable construction.

Mycelium on Board

From orange waste to a green future

Blueprint of fungal genomes

BioGov.net

Water-resistant mycelium composites

Sustainable Particle Board

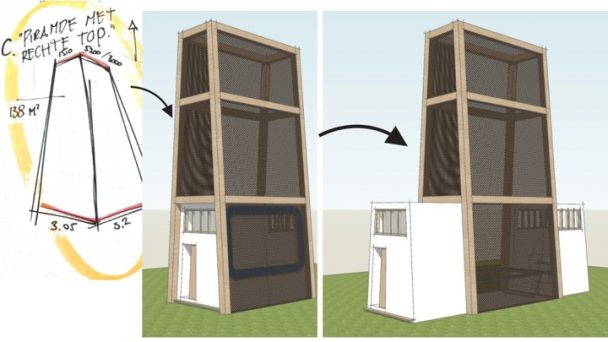

Circular Emergency Shelters

FACET

Totally Nuts: Circular Biobased Thermosets from Cashew Nutshells

Biodegradation Coatings Stahl

Green Hub: Information hub value chains green residual flows

Acceleration of nature-inclusive area development

Reflow

Biobased Insulation – Lifespan Determination (BILD)

Setting up and performing biodiesel trials in a coaster ship

Mythic

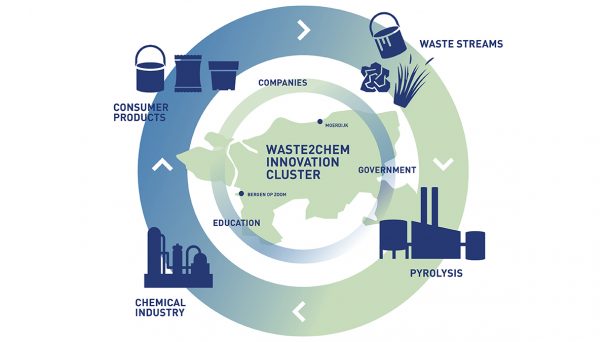

PyroCHEM: Waste2Chem Innovation Cluster

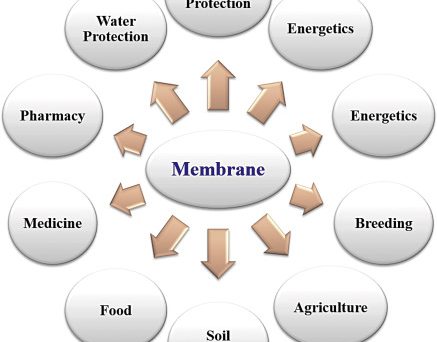

Membrane Technologies

Flestic

Direct extrusion of PHA-rich biomass

Production of bioplastics from residual streams (WoW! Capitalisation)

Powering Agrifood

Smart Circular Bridge

Fungal Colourants

Learning Network Biobuilders

Orange in the Sea

Amino Acids!

Building on Mycelium

Follow-up S4G

Colour Application Centre

Making disposables disposable

Making shipping more sustainable (Russia – Benelux)

Zircular Seaweed food

Extraction of pectins from onion skins

Growing Leather

Learning Community Renewable fuels

PHA accumulation capacity of Sewage Treatment Plant

NACO – Zero Waste Collective Oosterhout

Bio Iso (RAAK MKB)

Design with RRM (rapidly renewable materials)

Resin biodegradation

Biobased gadgets

Biobased foam

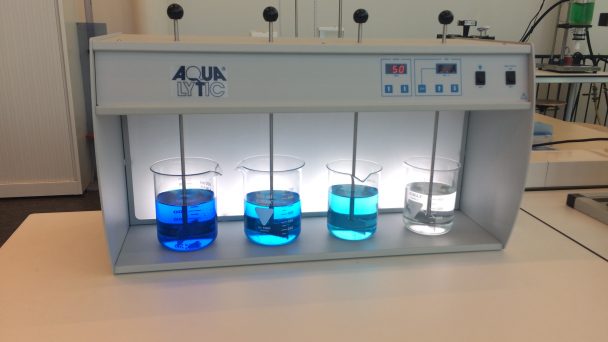

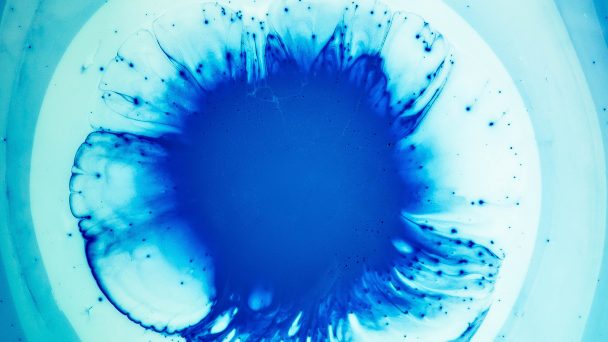

Biobased flocculants for water purification

Viberscrete – biobased concrete

Innovation Traineeships

Building light

BioADD

CurCol

Learning community

Professors’ platform Biobased Economy

Porter’s lodge Delfland

Smart Circular Bridge

Biobased, circular Christmas bauble with packaging

Mycelium boards

Coloring Mycelium

Back to the Materials of the Future

National Biobased Database

Structural Health in Biobased Constructions

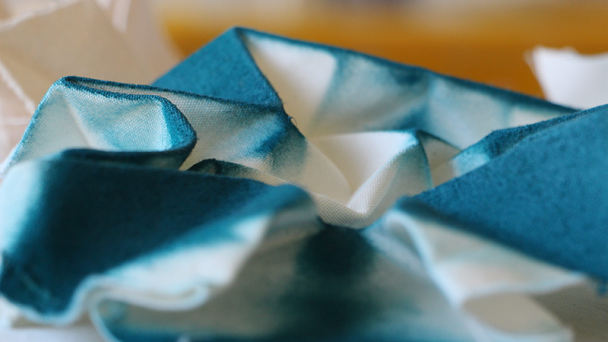

Beauti-Fully Biobased Fibers

Coffee Silverskin Biomass Utilization

Sustainable solid biofuels

Biobonding: Improved biocomposites

ZCORE (from Seaweed to COating Resin applications)

Cashing cashew

Material research for 3D printing

Seaweed Sterols

Onion deserves more

Circling in construction

Biomass flows in the province of South Holland

Circular Bio-based Construction Industry (CBCI)

Biodegradability of biopolymer and biopolymer composites

BBM+

Opportunities for composting in Brazil

Stadsjutters Breda

Innovation tables

Tomatozyme

MAA’s from algae

Sensor wise Biobased

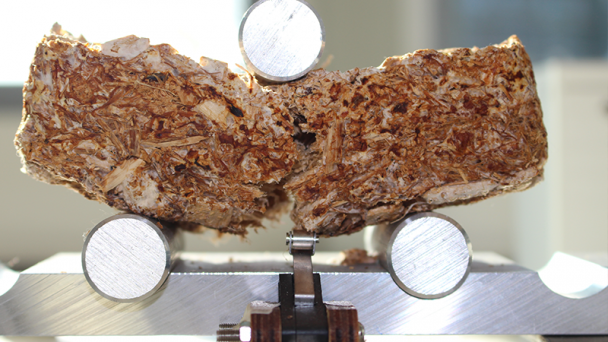

Pyrolysis Experimental Garden South

Grassification

REFAWOOD

Valuable ONION

Biobased Network

Living Lab Biobased Brazil

Biopolymer Application Center

Borderless Biobased Education

Living Colors

Mycelium

BioCOLOUR

BioCannDo

Blue Chain

WOW!

Green Growth

Biobased Challenge

Biobased bridge

Pure Nature: 100% Biobased

National Biobased Knowledge Network